Introduction

In the push for renewable energy solutions, photoelectrochemical (PEC) water splitting emerges as a promising technology for sustainable hydrogen production. By leveraging sunlight to split water into hydrogen and oxygen, PEC systems offer a clean, efficient pathway to green hydrogen. Recent advancements focus on heterojunction materials, where hematite (α-Fe₂O₃) and silicon (Si) combine to overcome challenges like light absorption, charge separation, and achieving required electrochemical potentials.

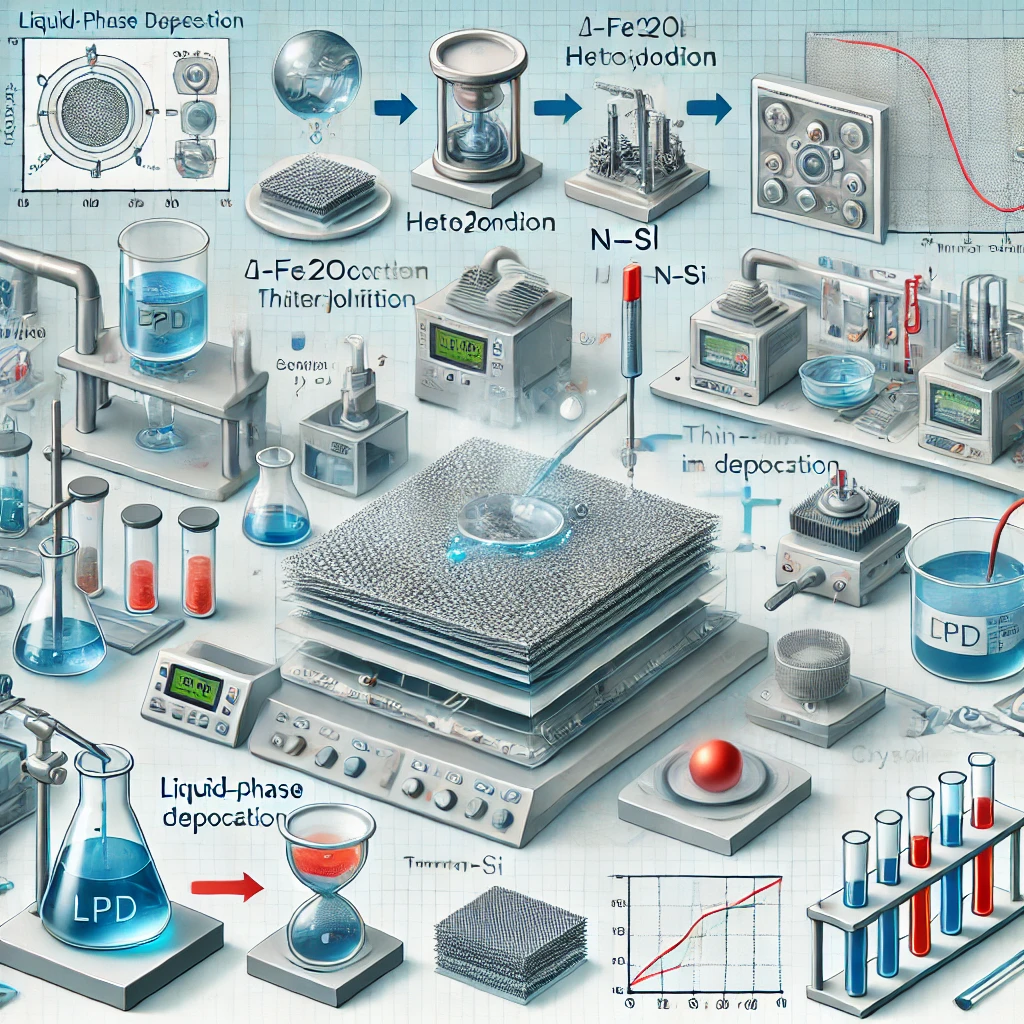

Innovative Liquid-Phase Deposition (LPD) Method

Among various fabrication techniques, Liquid-Phase Deposition (LPD) stands out due to its simplicity, cost-effectiveness, and scalability. A recent study demonstrates the synthesis of α-Fe₂O₃/n-Si heterojunction thin-film photoanodes using the LPD method, a first in the field. This innovation enables high-quality film production with enhanced photocurrent responses, making it ideal for unassisted PEC water splitting.

Key advantages of LPD include:

- Cost Efficiency: Minimal equipment and operational costs.

- Scalability: Easy adaptation for large-scale applications.

- Quality Control: Produces films with superior crystallization and minimal defects.

Experimental Approach

The fabrication process involved:

- Synthesis of Iron Nitrate Precursors: Derived from ferrous sulfate and lead nitrate.

- Creation of β-FeOOH Particles: Using ammonium hydroxide and atmospheric oxygen.

- Formulation of LPD Solutions: Integrating β-FeOOH and boric acid to optimize reaction conditions.

- Thin Film Deposition on n-Si Substrates: Controlled immersion for durations up to 72 hours.

- Thermal Treatment: Enhancing crystallization through annealing.

Results and Insights

- Structural Analysis: SEM and EPMA revealed multilayer structures with clear grain boundaries, confirming successful film fabrication.

- Crystallinity: XRD patterns highlighted enhanced α-Fe₂O₃ formation with prolonged deposition and annealing.

- Photocurrent Performance: The α-Fe₂O₃/n-Si heterojunction exhibited superior light absorption and photocurrent density compared to conventional FTO substrates.

- Energy Efficiency: The onset potential for photocurrent was reduced by 0.3 V, a significant leap toward unassisted water splitting.

Challenges and Future Directions

While the LPD-fabricated photoanodes show promise, challenges remain:

- Efficiency Optimization: Further reducing onset potential to achieve theoretical limits.

- Stability: Addressing performance degradation over extended operation.

- Scalability: Transitioning from lab-scale to industrial applications.

Future research aims to refine material interfaces and explore Z-scheme configurations that mimic natural photosynthesis, utilizing dual semiconductors for enhanced solar-to-hydrogen conversion.

Conclusion

The adoption of LPD for α-Fe₂O₃/n-Si photoanodes represents a breakthrough in green hydrogen technology. This cost-effective and sustainable approach aligns with global energy goals, paving the way for efficient PEC systems. As we advance, the integration of such innovations holds the potential to revolutionize hydrogen production, fostering a cleaner, greener future.